Shapeways Black Friday Sale

Shapeways is offering two options for Black Friday with 20% off of orders over $75 OR Free Worldwide Shipping on orders of any value.

For 20% off orders of $75 or more, please enter tdzmu at checkout

OR for free worldwide shipping on orders of any value, enter v9v7r

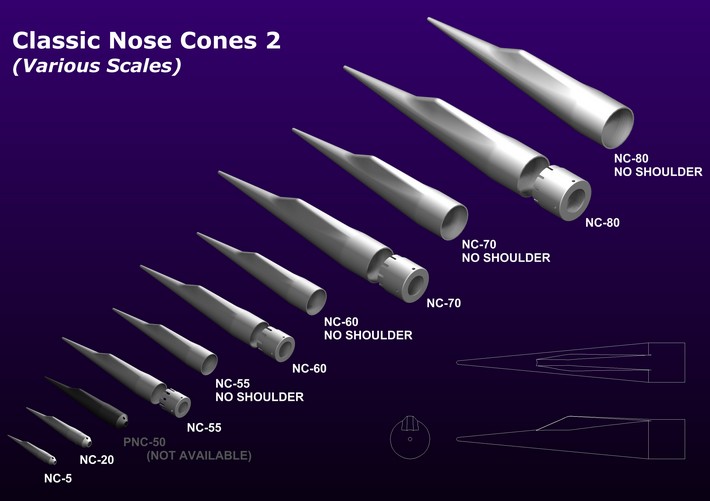

Also, as of this morning, our nose cone prices … Continue Reading ››